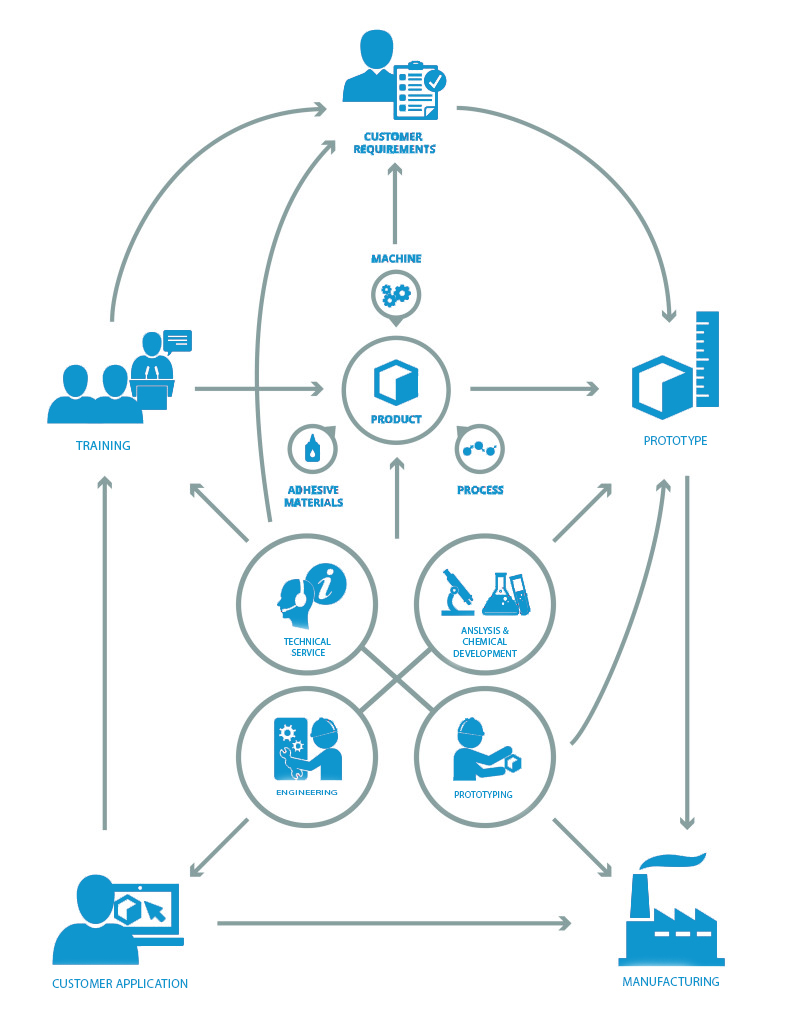

Here at James Dewhurst we have applied the skills of our dedicated textile research and development team to develop products, machinery and processes capable of manufacturing solutions to the most demanding customer reinforcement problems. This knowledge can also be applied to resolving problems in customer manufacturing processes by further tailoring the solution to the customer’s particular production needs.

With such a strong skill set and a desire to develop new solutions via textile research by putting customer needs at the centre of the problem solving process, James Dewhurst is a development partner that you can rely on to find the solution to your problem.

Product Design

The textile research and development process starts with product design, which entails understanding what our customer needs and how our product needs to work in their process. Through this process we develop a thorough understanding of what is important.

The first step is to determine what yarn types and weights are required and what construction (number of ends per cm and number of picks per cm) are required for the level of reinforcement needed. This construction is carefully designed to meet the tensile and functional requirements of the customer.

Next we look at what binder is required. This is particularly important if there is a need for the yarn to have other properties, such as fire retardence, abrasion resistance or electrical conductivity. Both the type and amount of binder are critical in this step. The combination of construction and binder is engineered to deliver the behaviour and performance critical to the function and application of the technical textile.

Finally, we examine how the customer wants to receive the roll, for example what width, what cores, how should the roll be packed. This results in a final product that is tailored to the customer’s application and equipment.

This information enables us to examine our core range for a suitable existing product, or if none is available provides a design brief against which we can develop a new product.

Design Flexibility

Our team of technical managers will support and guide you through the process of selecting the most suitable fabric for your reinforcement need. Whether your need results in a core product that is routinely manufactured, or a bespoke product that is tailored specifically to your process, we have the expertise and experience to support your business. Having a design team that includes machinery design means that some of our production equipment has been built specifically to manufacture speciality bespoke products.

Challenge Us To Find Your

Reinforcement Solution

At James Dewhurst, we take pride in our dedicated technical experience with woven, laid, and laminated textiles. It’s our job to work closely with our customers on a variety of new projects not only as suppliers, but as developers. This involves getting to know you and your project needs inside and out, so that we can dedicate ourselves to creating the ideal solution for you.

Do you have an idea or project in mind that James Dewhurst can bring to fruition? If so, we want to be your partner. Please contact a member of our team to find out more information.