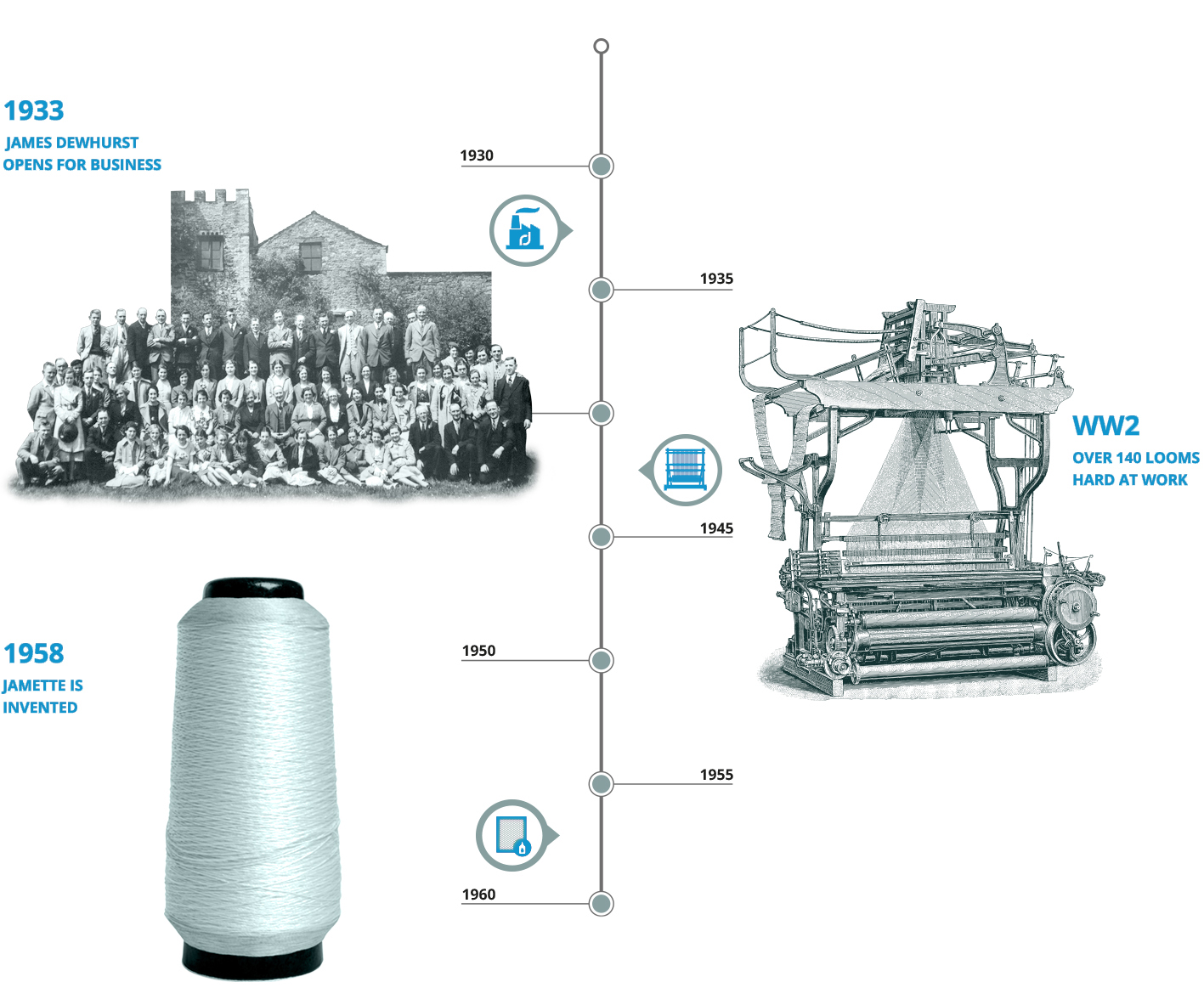

1933: THE BEGINNING

In 1933, James Dewhurst opened his business in Clitheroe, Lancashire. At the time, Lancashire was the home of textiles in Europe, and Dewhurst worked hard to establish himself as a brilliant innovator in the textile industry. Dewhurst adapted looms and weaving processes to produce uncommon fabrics for the time.

WW2: SLOWLY PROGRESSING

A few short years after Dewhurst opened for business, during the Second World War, James Dewhurst had over 140 looms in operation. Following this, technical textiles entered the market in the 1950s, causing the company to face new challenges as the plastic and rubber industry began looking for open mesh scrims made from high tenacity yarns.

1958: ENTER JAMETTE

James Dewhurst spent the last three years of his working life finding a solution to this challenge; a level of patience and commitment that was rewarded with the launch of a new class of technical textile scrims, patented under the name “Jamette.” Jamette became the forerunner of James Dewhurst’s high performance woven and laid scrims, now known as Dewlock and Dewtex.

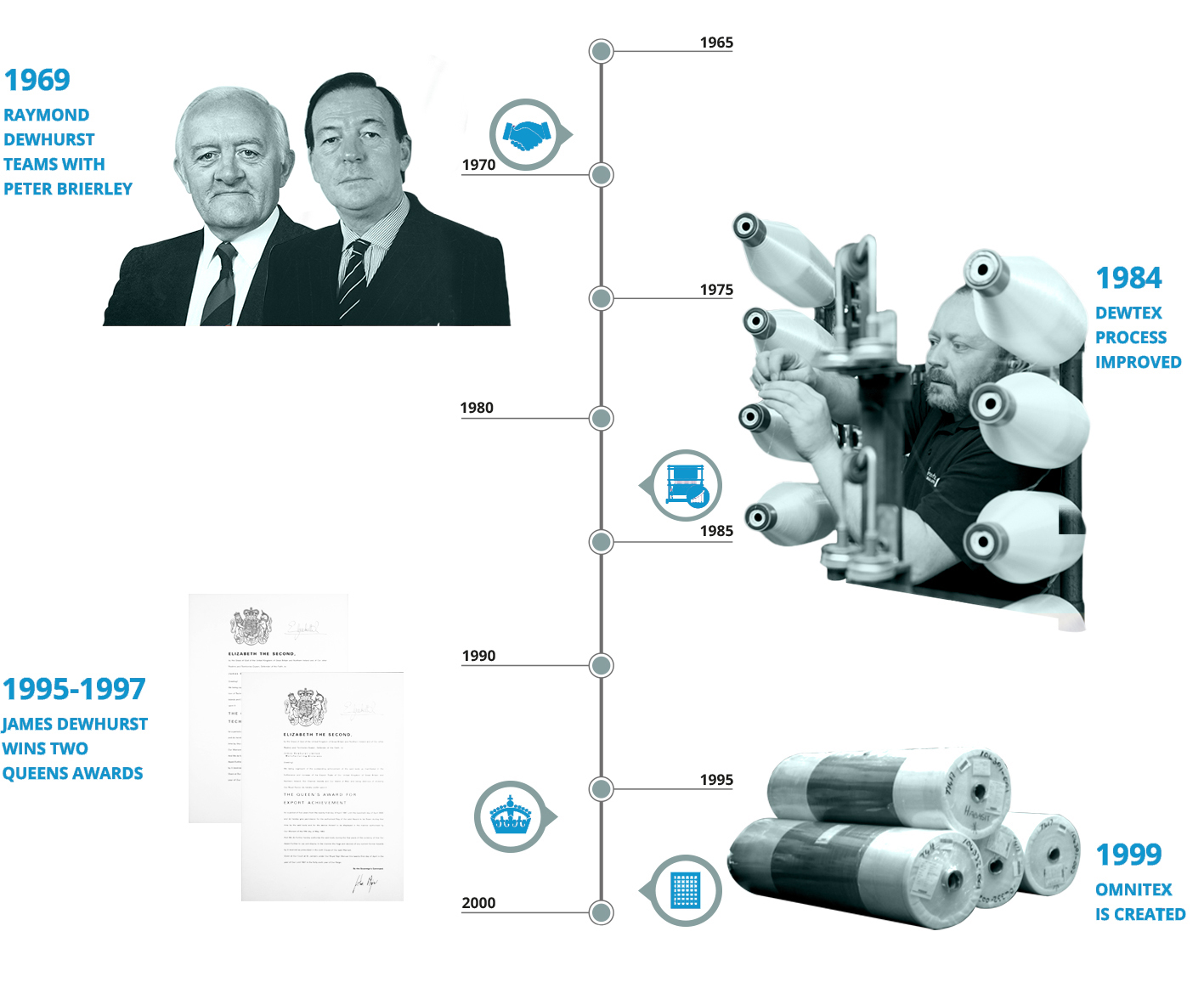

1969: A NEW PARTNERSHIP

By 1969, James Dewhurst was focused entirely on industrial textiles. James’ son Raymond subsequently teamed up with Peter Brierley under whose management the business continued to grow with additional woven scrim capacity. The company also started to source industrial textiles from around the world.

1981: MODERNISATION SPEEDS UP THE PROCESS

Under newcomer Paul Cooper’s technical stewardship, James Dewhurst went on to develop its own proprietary laid scrim technology now known around the world as Dewtex™. This unique process could produce scrims at over 3 times the speed of conventional turbine looms and twice the width.

1995 – 1997: QUEEN’S AWARDS

In the mid-90s, James Dewhurst was presented with two Queen’s Awards, noting their achievements in the field. In 1995, James Dewhurst received the Queen’s Award for Technology Achievement, and in 1997, they received the Queen’s Award for Export Achievement.

1999: OMNITEX HITS THE MARKET

Further innovations followed when James Dewhurst launched its first off-line coating and laminating unit in 1999, which led to the firm providing its customers with a range of coating substrates by combining nonwoven materials with scrims. Now marketed as Combitex, the creation of this technology led to an entire factory being opened to support demand.

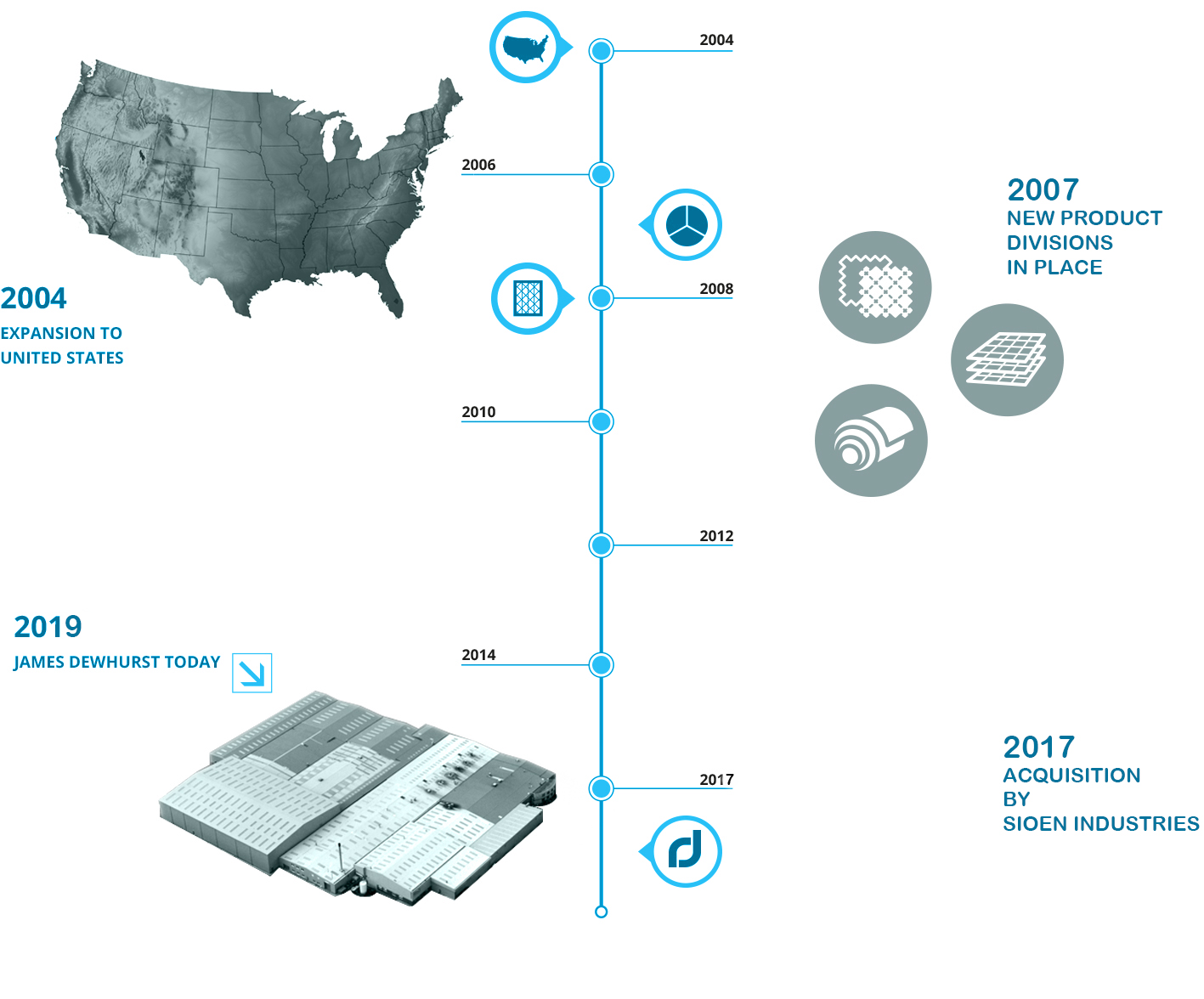

2004: STATESIDE SUCCESS

Global demand for Dewtex was on the rise, and in 2004, a decision was made by the Dewhurst family to expand into the US, with a factory established the same year. From 2004 until 2010 this factory was predominantly used for additional capacity for the European markets while the company worked on developing a market in the US.

2007: DIVIDING THE BUSINESS

After the surge of innovation over the past ten years, James Dewhurst boasted three key product divisions by 2007: traditional industrial textile solutions, laminated scrims, and reinforced scrims. James Dewhurst’s factory in the US increased in capacity in line with the introduction of Triatex, a laid scrim with yarn woven in three directions instead of two. These triaxial scrims are well-suited for ducting applications.

2017: ACQUISITION BY SIOEN INDUSTRIES

2019: JAMES DEWHURST TODAY

Having sold more than one billion square metres of flexible reinforcement materials in 47 countries over the last two years alone, the company has enjoyed steady success despite the economic downturn, thanks to the company’s new focus on delivering quality customer service. James Dewhurst is keen to continue its tradition for innovation by focusing on opportunities in the geotextile/construction market through the development of higher Decitex yarns.

Challenge Us To Find Your

Reinforcement Solution

At James Dewhurst, we take pride in our dedicated technical experience with woven, laid, and laminated textiles. It’s our job to work closely with our customers on a variety of new projects not only as suppliers, but as developers. This involves getting to know you and your project needs inside and out, so that we can dedicate ourselves to creating the ideal solution for you.

Do you have an idea or project in mind that James Dewhurst can bring to fruition? If so, we want to be your partner. Please contact a member of our team to find out more information.